FRESHLINE dostarczamy najwyższej jakości sałaty i warzywa

Z dumą produkujemy warzywa i sałaty dla największych sieci handlowych. Łączymy tradycję z nowoczesnością w trosce o środowisko i zdrowie naszych klientów.

Zawsze świeże produkty

Od młodych listków po gotowe zestawy

Z miłości do tego co robimy

Wkładamy całe serce w każdy nasz produkt

Zdrowe i gotowe do spożycia

Wspaniały smak i zdrowie to podstawa naszych produktów

Posiadamy Certyfikaty

GLOBAL G.A.P. | HACCP | BRC

Nasza oferta

Przygotowane z miłości do świeżości. W naszej ofercie znajdują się gotowe do spożycia mieszanki sałat, mono produkty oraz lunchboxy w różnych wariantach. Mamy również ofertę produktów BIO. Wybierz kategorię produktów i poznaj gotowe propozycje.

O nas

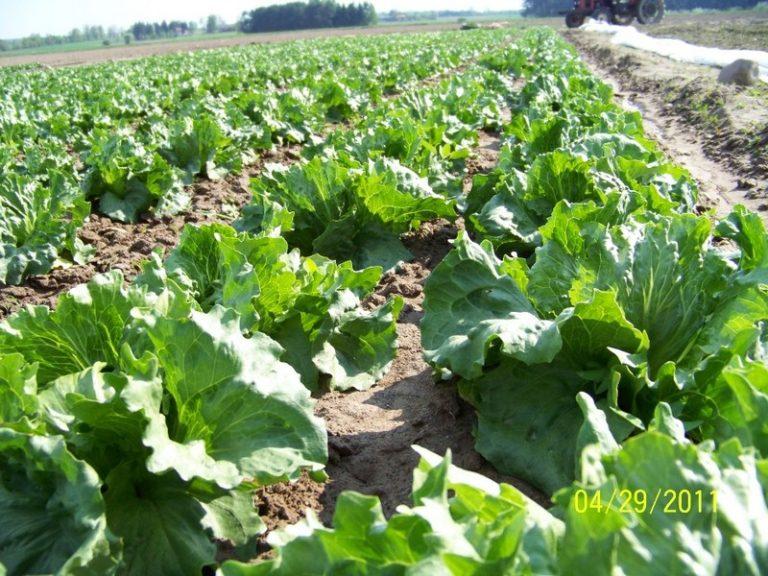

Firma AVIT rozpoczęła swoją działalność w 2001 roku. Wtedy to rozpoczął się proces budowania firmy oparty o najwyższy poziom jakości, wspomagany przez nowoczesne technologie i przyjazny środowisku naturalnemu. Obecnie zajmujemy się produkcją najwyższej jakości świeżych warzyw oraz sałat FRESHLINE.

Jakość poparta certyfikatami

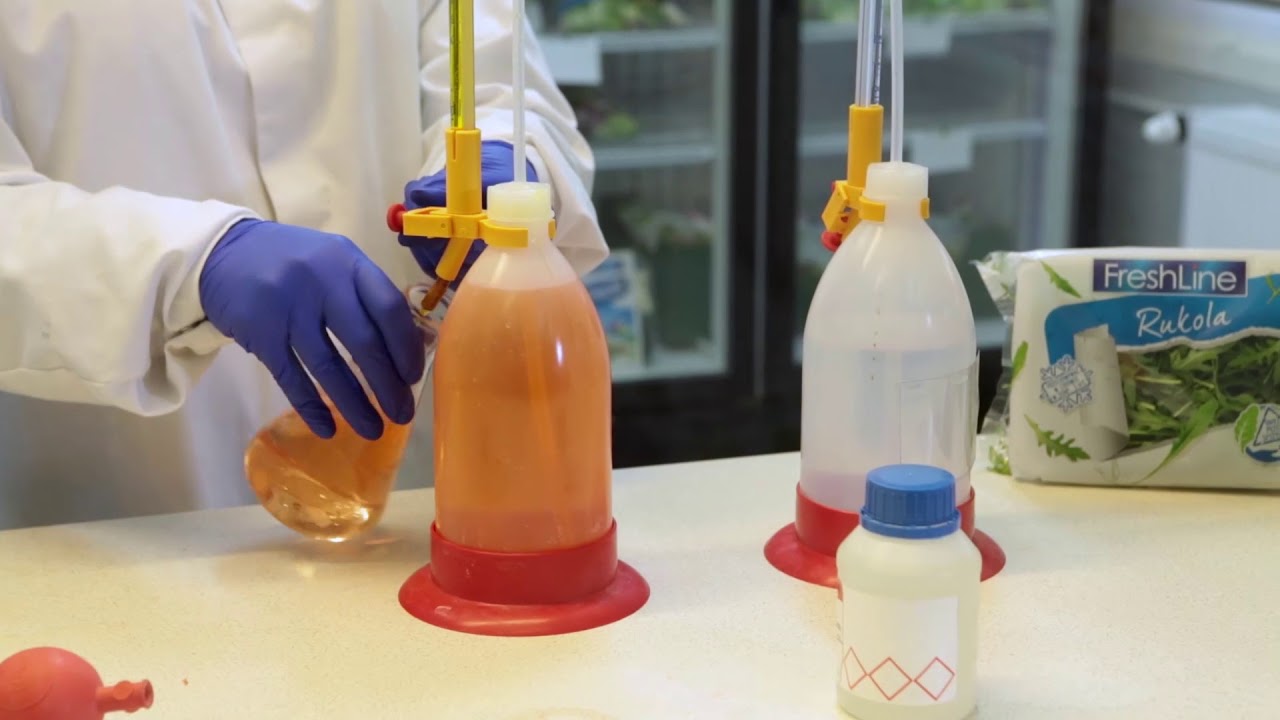

Wieloetapowy system kontroli procesu produkcji oraz prowadzony monitoring w czasie uprawy, zbioru i przechowywania pozwala spełnić najwyższe standardy na każdym etapie i w efekcie dostarczyć naszym Klientom wyroby o stałej, gwarantowanej jakości.

Zobacz, jak wygląda nasza produkcja

Potrzebujesz mieszanki sałat? Mono produktów? Lunchboxów? Dobrze trafiłeś!

Poznaj naszą pełną ofertę lub zadzwoń do nas, odpowiemy na wszystkie pytania i przedstawimy Ci najlepsze rozwiązania.

lub